Products

Filters

Files for Duratron CU60 PBI

Files for Duratron T4301 PAI

Files for Duratron T4501 PAI

Files for Duratron T5530 PAI

Files for Duratron D7000 PI

Files for Ketron PEEK 1000

Files for Ketron TX PEEK

Files for Ketron CA30 PEEK

Files for Duratron PEI

Files for Techtron HPV PPS

Files for Sultron PSU

Files for Tetron S

Files for Tetron G

Files for Tetron C

Files for Tetron B

Files for Tetron GR

Files for Ticomp S

Files for Ticomp BG

Files for Ticomp HVM

Files for Ticomp MD

Files for Tetco V

Files for Chemfab

Files for Chemlam

Files for Chemstik

Files for Ertalon 6SA

Files for Ertalon 66SA

Files for Ertalon 6PLA

Files for Ertalon LFX

Files for Ertalon 6XAU+

Files for Ertalon 66GF30

Files for Nylatron GS

Files for Nylatron GSM

Files for Nylatron MC901

Files for Nylatron NSM

Files for Nylatron 703XL

Files for Ertacetal C

Files for Ertalyte PET-P

Files for Ertalyte TX PET-P

Files for Polystone PG100

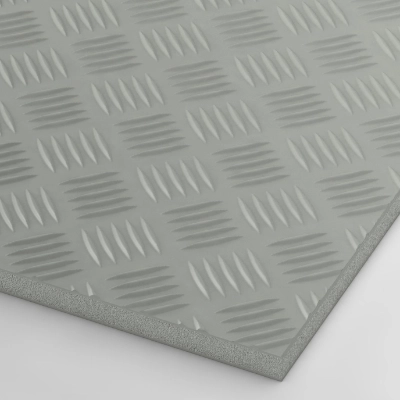

Files for Polystone PG100 Checker Plate

Files for Polystone D 500

Files for Orkot C320 (TLG)

Files for Orkot C321 (TL)

Files for Orkot TLM Marine (TLMM)

Files for Polystone Matrox

Files for Polystone FM (Fender)

Files for Polystone M PIR (ReLoop)

Files for Polystone MR

Files for Polystone MR AST

Files for Resistawear

Files for Polystone Marine-Tec

Files for Polystone PG100

Files for Polystone P Homopolymer UV

Files for Foamlite/Uniboard ECO

Files for Polystone Matrox

Files for Polystone PG100 Checker Plate

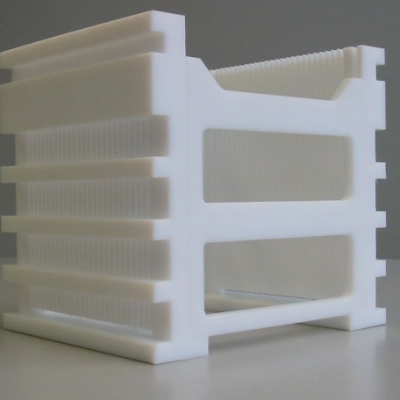

Files for Polystone G CubX PG100

Files for Polystone P CubX

Files for Steel Chain Straight Running / Side Flexing

Files for Plastic Chain Straight Running / Side Flexing

Files for Grip Top Chain

Files for Low Back Pressure Chain

Files for Gripper Chain & Accessories

Files for Carrier Chain (Crate Chain)

Files for Plate Top Chain

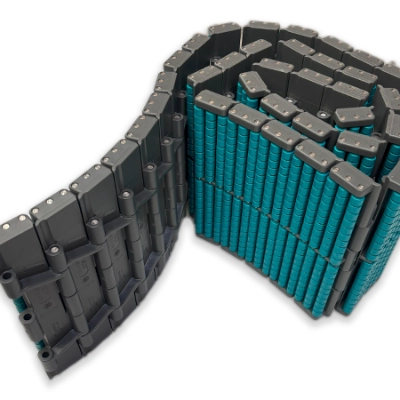

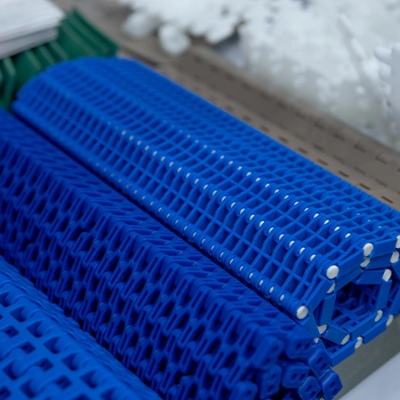

Files for Straight Running Modular Belt/Components

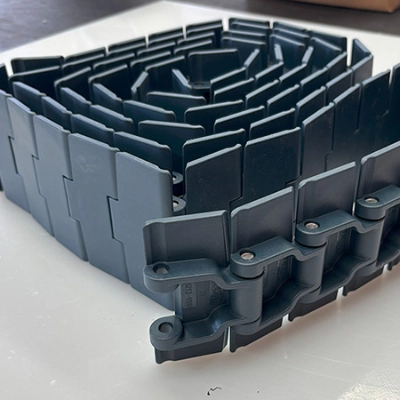

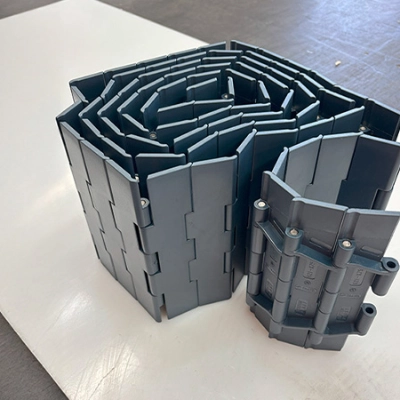

Files for Side Flexing Modular Belt/Components

Files for Miscellaneous Belts/ Components

Files for Chemfab

Files for Chemlam

Files for Chemstik

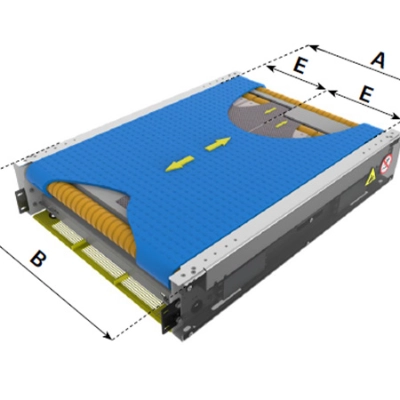

Files for Diverter Station (Modsort)

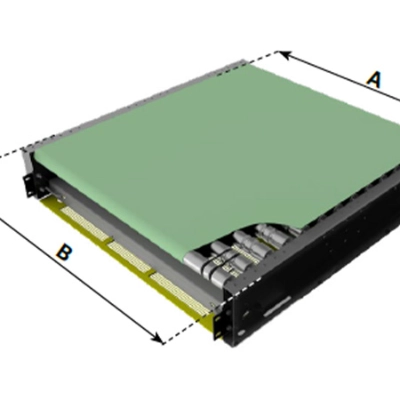

Files for Intermediate Conveyors

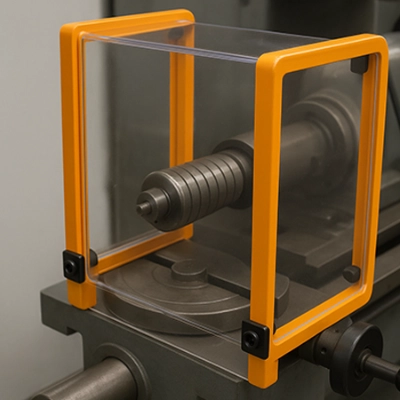

Files for ICOF Condition Monitoring

Files for Resistawear

Files for Frame Structural Components

Files for Connecting Clamps

Files for Frame Support Components

Files for Articulated Feet

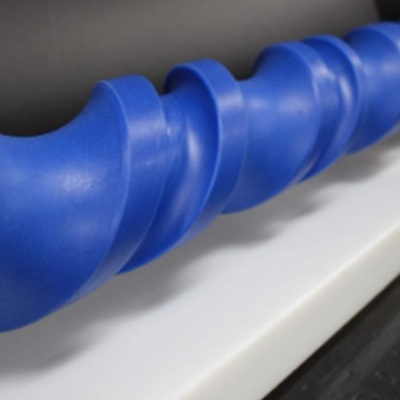

Files for Chain Return Components

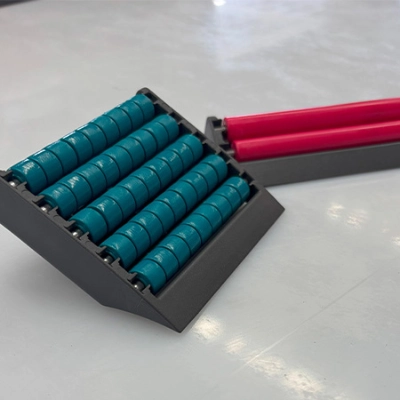

Files for Roller Guides

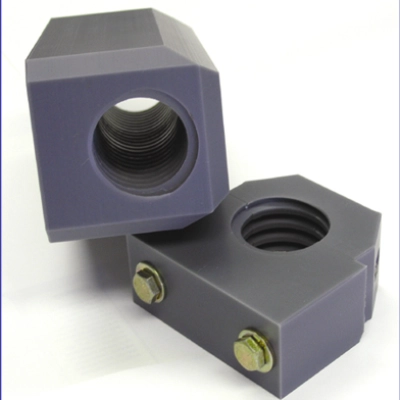

Files for Bearings in Plastic Housing

Files for Side Guide Components

Files for Sprocket for Straight Running Chain

Files for Sprocket for Side Flexing Chain

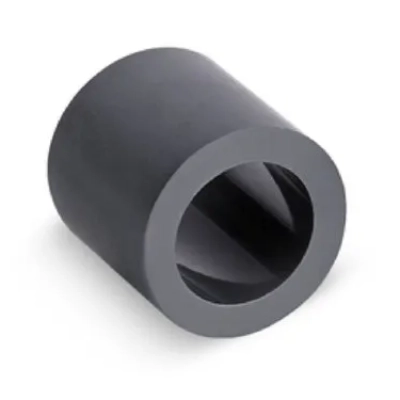

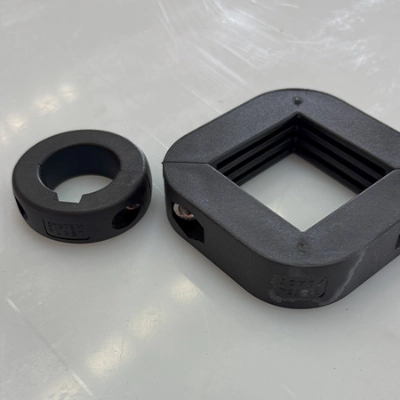

Files for Sprocket other (shaft collar)

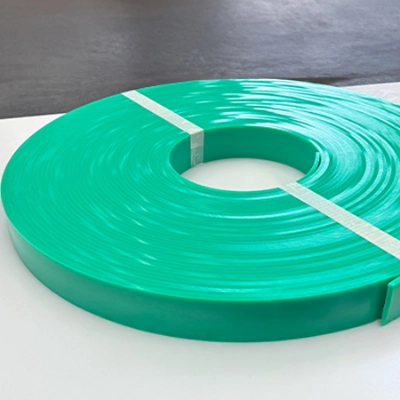

Files for S-Ply Yellow

Files for S-Ply Yellow HT

Files for S-Ply Blue

Files for S-Ply Carbon

Files for S-Ply Carbon Blue

No products found

There are no products matching the current filters. Try adjusting your search criteria.