-

Products

Back

Products

-

Extreme Engineering Plastics

-

Advanced Engineering Plastics

-

Engineering Plastics

-

Industrial Plastics

-

Specialty Plastics

-

-

Industries

Back

Industries

- Applications

-

Back

Insights

Dotmar Cookie Consent

This site uses cookies to provide you with rich content intended to improve your overall user-experience. For more information, please refer to our Privacy Policy, and Terms.

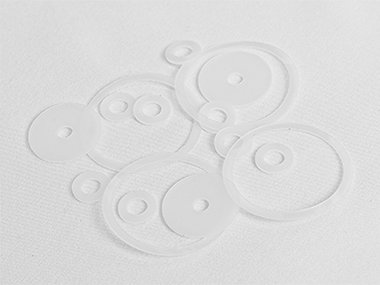

Gaskets

What is a Plastic Gasket?

A plastic gasket is a sealing component that is designed to fit between two surfaces to prevent leakage of fluids or gases under compression. Plastic gaskets are commonly used in various industrial applications where a tight seal is necessary, such as in pumps, pipes, and manifolds. Plastic gaskets offer advantages such as resistance to corrosion, chemicals, and temperature variations, depending on the specific type of plastic used in their construction. They come in different shapes, sizes, and designs to accommodate various sealing needs.

Benefits of Custom Machined Plastic Gaskets

-

Chemical Resistance - Plastic gaskets such as Tetron S are resistant to a wide range of chemicals, acids, and corrosive substances, making them suitable for applications where exposure to such materials is common.

-

Temperature Resistance - Certain types of plastic gaskets can withstand extreme temperatures without losing their sealing properties, making them suitable for both high-temperature and low-temperature applications.

-

Cost-Effectiveness - Custom machined plastic gaskets are cost-effective to manufacture especially when small quantities are required.

-

Electrical Insulation - Generally plastic gaskets provide electrical insulation properties, making them suitable for sealing electrical enclosures or components where insulation is necessary.

-

Durability - Engineering plastic materials can offer excellent durability and resistance to wear, tear, and deformation over time, leading to longer service life and reduced maintenance needs.

-

Environmental Resistance - Plastic gaskets can be engineered to resist environmental factors such as moisture, UV radiation, and ozone, making them suitable for outdoor or harsh environment applications.

Dotmar has qualified engineers that can provide direct support with plastic material selection for gaskets.

Envelope Gaskets

Generally made from Tetron S to protect an elastomer providing the necessary elasticity.

Flange Gaskets

Generally used for pipe flanges or similar applications

Sheets Gaskets

Flat gaskets that are versatile and can be easily customised.

Washer Style

Often made from Polystone 7000 or Ertalon 6SA

Elastomeric Gaskets

A more elastic material that is able to provide sealing for a level of unevenness between surfaces.

Material selection is a critical consideration when choosing plastic for gaskets, as it directly impacts the performance, durability, and maintenance requirements of these components. Here are some key material selection considerations for plastic gaskets:

-

Chemical Resistance

Understanding the chemicals resistance requirements is imperative when selecting a suitable material, to ensure that the materials will withstand the chemical needs of the application.

-

Sealing ability & Hardness.

The material must have appropriate properties that will ensure the gasket seals, and has suitable hardness to withstand the clamping pressures.

-

Availability

The material should be available in a shape and/or thickness that will allow it to be machined or cut to the required size, shape and thickness.

-

Regulatory Requirements

Does the application have regulatory requirements such as food contact or drinking water.

Contact us

Dotmar Engineering Plastics stands poised to address your unique challenges. Harness our expertise for bespoke engineering plastic solutions tailored to your specifications.

Subscribe

To receive latest news and promotions